Rivnuts (also known as nutserts, blind nuts, or threaded inserts) are a fast, reliable, and cost-effective way to create strong, load-bearing threads to thin or brittle materials—especially when access to the back is limited. They are installed into a parent material, allowing a secondary component to be securely bolted in place.

Designed as a variation of a standard rivet, rivnuts feature a tubular body (round, knurled or hexagonal) with internal threading. They can be installed in sheet materials as thin as 0.50mm and offer one-sided (blind) installation, making them a versatile solution for many applications.

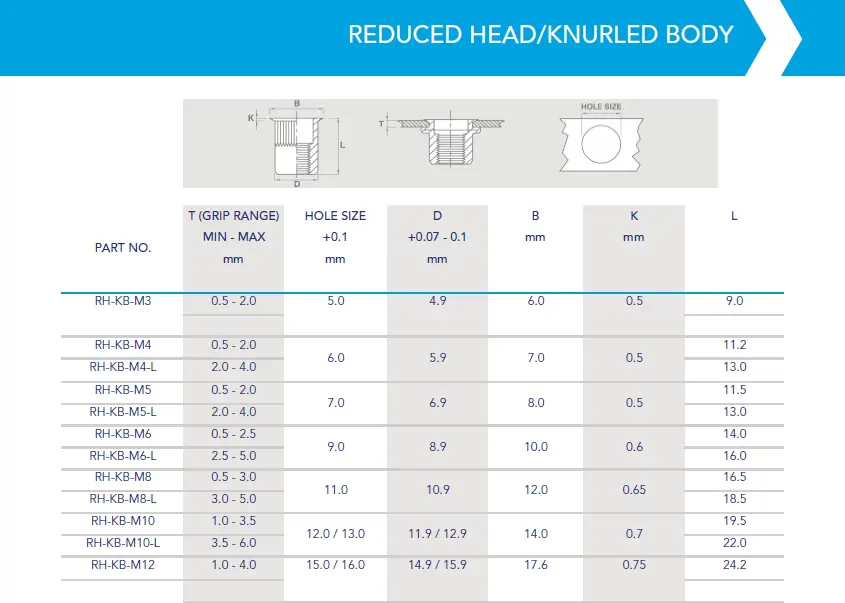

Reduced Head, Knurled Body rivnuts provide a low-profile, high-grip fastening solution, ideal for tight spaces and vibration-prone applications.

- Reduced Head – A smaller, low-profile head allows for a flush installation, making it perfect for applications where clearance is limited or aesthetics matter.

- Knurled Body – Features vertical grooves that improve resistance to spinning in round holes, ensuring a more secure hold, especially in soft or thin materials.

Commonly used in automotive, electronics, furniture, and industrial applications, these rivet nuts provide a secure, non-rotating, and low-profile threaded insert. They are available in steel, in sizes M3 to M12.