Rivnuts (also known as nutserts, blind nuts, or threaded inserts) are a fast, reliable, and cost-effective way to create strong, load-bearing threads to thin or brittle materials—especially when access to the back is limited.

They are installed into a parent material, allowing a secondary component to be securely bolted in place.

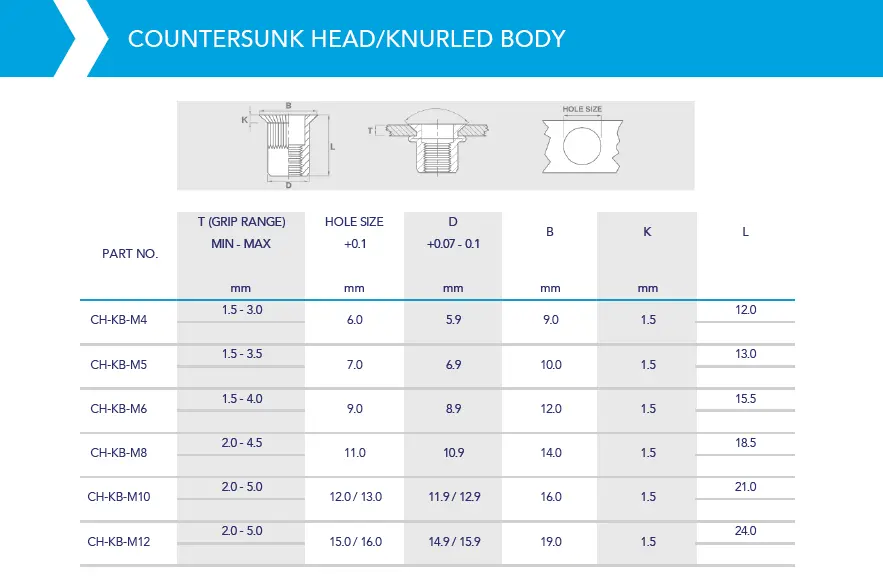

Designed as a variation of a standard rivet, rivnuts feature a tubular body (round, knurled or hexagonal) with internal threading. They can be installed in sheet materials as thin as 0.50mm and offer one-sided (blind) installation, making them a versatile solution for many applications.

Countersunk Rivnuts, function similarly to standard rivnuts but feature a countersunk head, allowing them to sit flush with the surface once installed. They are ideal for applications where a smooth, seamless finish is essential, such as in automotive (securing interior panels for a clean look) or aerospace applications (ensuring a flush exterior on aircraft for best aerodynamics).

Application:

These rivnuts are installed using the same method as regular rivnuts; however, the installation hole must also be countersunk to ensure a flush fit. Additionally, the parent material must be slightly thicker compared to standard rivnut applications, as the countersinking process removes extra material.