Rivnuts (also known as nutserts, blind nuts, or threaded inserts) are a fast, reliable, and cost-effective way to create strong, load-bearing threads to thin or brittle materials—especially when access to the back is limited. They are installed into a parent material, allowing a secondary component to be securely bolted in place.

Designed as a variation of a standard rivet, rivnuts feature a tubular body (round, knurled or hexagonal) with internal threading. They can be installed in sheet materials as thin as 0.50mm and offer one-sided (blind) installation, making them a versatile solution for many applications.

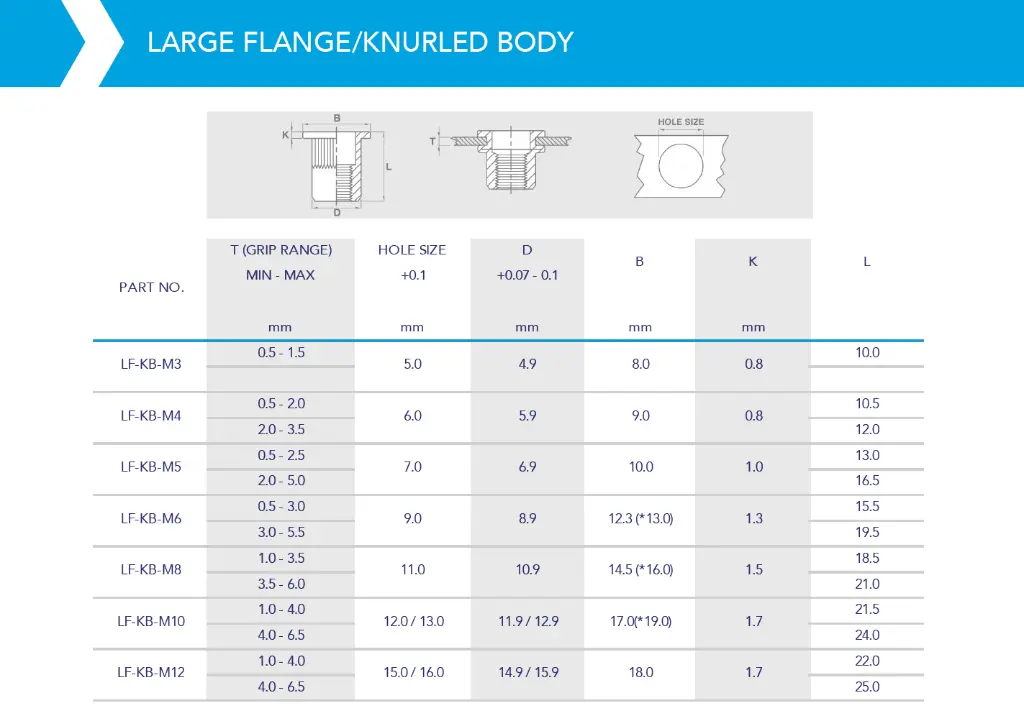

Large Flange, Knurled body, Closed End rivnuts combine three key features for maximum grip, load distribution, and protection in demanding applications:

- Large Flange Head – Provides a wider load-bearing surface, preventing pull-through in thin or soft materials.

- Knurled Body – Features vertical grooves that help prevent rotation, ensuring a secure fit even in high-vibration environments.

- Closed End – Seals off the back of the rivnut, preventing dirt, moisture, or contaminants from passing through, protecting both the fastener and internal components from corrosion and debris.